Add time:2025-10-09

Add time:2025-10-09 clicks:

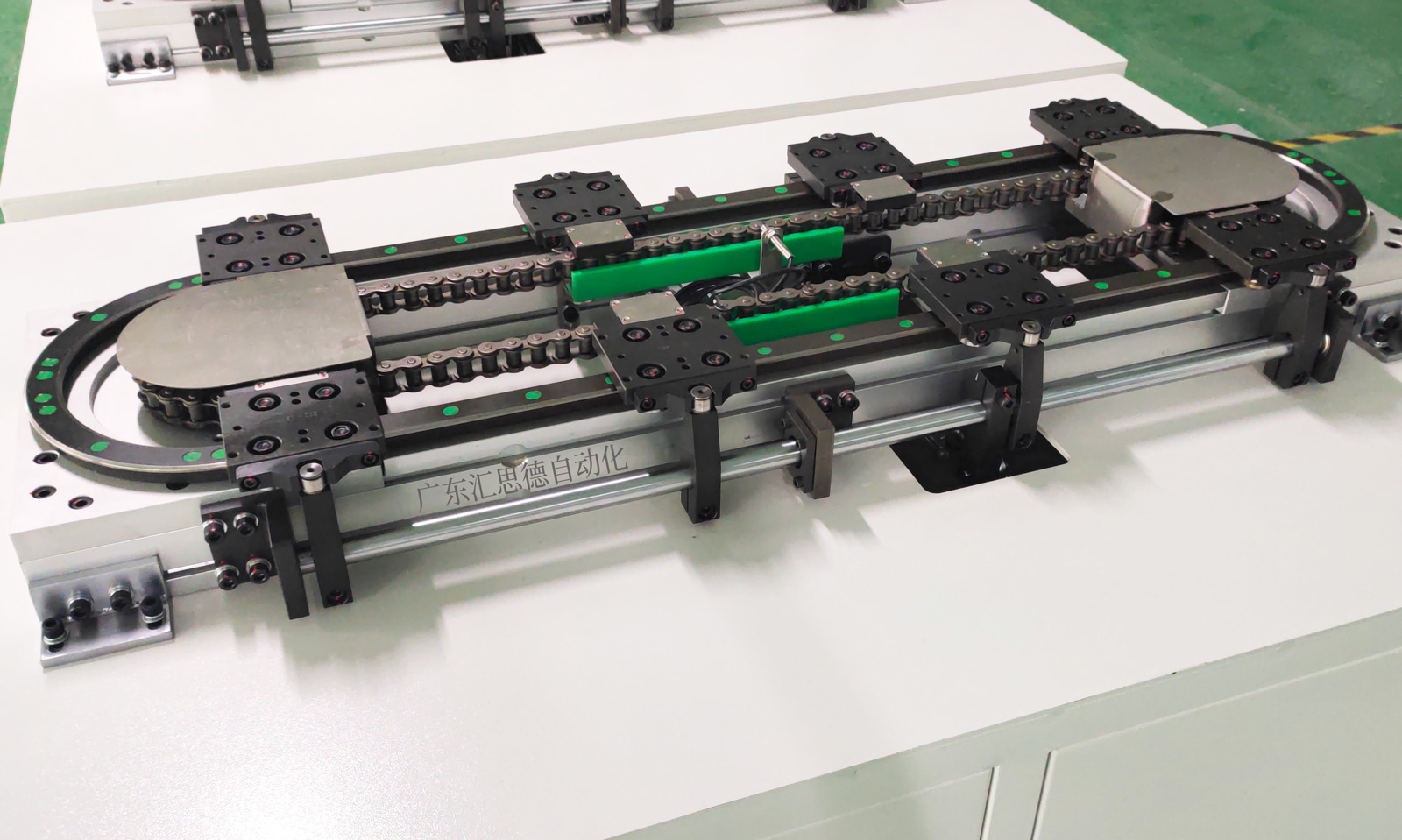

clicks: Huiside annular guide conveyor line is a high-precision circulating conveyor system specially designed for automated processing and assembly lines. It is constructed with a V-shaped annular guide rail and a precision drive control system to achieve stable circular motion. The system precisely connects multiple sliders through transmission modules (including timing belts, chains or connecting rods, etc.), and the main drive wheel drives the transmission assembly, which in turn drives the sliding seat to run smoothly along the annular guide rail. The system supports customized design, and can flexibly configure linear guide sections of different lengths and multi-specification annular guides (covering various sizes and angles) according to customer needs to meet the transportation needs of diverse annular production lines/circulating assembly lines.

High rigidity materialPrecision grinding and hardening of high-quality materials ensure high structural strength and long-term stability

Long-lasting: It has excellent anti-wear characteristics, high initial positioning accuracy, strong anti-pollution ability, and adapts to dust environment. Material selection fully considers the working environment (such as dust, humidity, temperature) and load characteristics. After special process pretreatment (such as precision forging, cryogenic treatment, etc.), the surface hardening process is implemented, which significantly improves the corrosion resistance, impact resistance and long-term stability of the guide rail.

efficient operation: Excellent running speed, low vibration, low noise, long maintenance cycle interval

Bearing steel materialHuiside annular guide rail conveyor line optimizes material selection for severe working conditions, and enhances the comprehensive performance of materials through special heat treatment process.

surface strengtheningThe hardening process significantly enhances the wear resistance and structural stability of the guide rail.

Patented V-track technologyHuiside independently developed the V-shaped guide system, and the contact surfaces between the roller and the guide rail are all processed with high-precision mirror.

Dynamic balance designThe V-type roller set with uniform force ensures a highly consistent running track, effectively avoids the deviation or vibration problems caused by the uneven force of the traditional guide rail, guarantees the precision and stability of the conveying process, and realizes high-precision motion control.

Flexible positioning solutionHuiside annular guide rail conveyor line supports cylinder slide, swing cylinder, electric slide, cam link and other positioning methods.

PneumaticCylinder slide table, swing cylinder positioning (fast response speed, suitable for short and medium stroke);

Electric: Electric slide positioning (repeated positioning accuracy ± 0.04mm, suitable for high-precision scenes);

MachineryCam linkage positioning (compact, suitable for special track requirements).

The system's secondary precision positioning system has high accuracy and reliability, with a maximum repeat positioning accuracy of ± 0.05mm. Without secondary positioning mode, the basic positioning accuracy is ≥ ± 0.5mm, which can simultaneously meet the differentiated needs of high-precision assembly (such as electronic components) and conventional transportation (such as packaging processes).

Servo drive systemHigh-precision servo motors (multi-brand optional) are standard on the Huiside ring guide conveyor line, providing excellent start-stop control and initial positioning accuracy.

Ring guide rail conveyor line transmission mode adaptation:

Heavy duty applicationsChain drive (large load, long stroke preferred, high-speed durability), suitable for large load (≤ 500kg), long stroke (> 10m) working conditions, using high-strength precision chain, wear resistance life > 10,000 hours;

High clean and low noise sceneSteel curtain synchronous belt drive (low noise, high cleanliness, high precision)

Quick response: Screw drive (high-speed sliding table linkage)

Flexible configurationSupport the optimization combination of chain, timing belt, cam plate, screw, connecting rod and other transmission forms.

integrated control: Huiside ring rail conveyor line is compatible with PLC programming system, can integrate PLC control system, support communication interaction with host computer (such as MES, SCADA) and peripheral equipment (sensors, robotic arms) (Modbus, Profinet and other protocols). Support custom setting of production parameters to realize intelligent unmanned operation of automated production lines.

efficiency improvementCircular guide rail conveyor line reduces manual intervention through automated control, optimizing production time and cost control.

Intelligent lubrication systemHuiside annular guide rail conveyor line slider has a built-in automatic lubrication device, which only needs to be replenished with lubricating oil regularly, greatly reducing the maintenance workload.

Low maintenance designThe main structure of the annular guide rail conveyor line realizes long-term stable operation almost maintenance-free. The main structure (such as guide rails and transmission components) adopts maintenance-free design, and the quality assurance time of key components (such as servo motors and reducers) is long. The maintenance cost of the whole life cycle is reduced by more than 50% compared with traditional products.

Typical application fieldsHuiside circular guide rail conveyor line is widely used in food processing (baking, sorting), precision packaging (electronic components, medicine), automatic marking (laser/inkjet), surface coating (auto parts), new energy (lithium battery pole sheet handling), semiconductor (wafer transmission) and automotive manufacturing (seat assembly, instrument panel installation) and other fields

core value: Significantly improve production efficiency, optimize space utilization, and achieve the goal of reducing costs and increasing efficiency. The annular guide rail conveyor line can increase the space utilization rate of the production line by 25% -40%, increase production efficiency by more than 30%, and reduce the material damage rate through precision conveying (such as a 90% reduction in the scratch rate of electronic components), helping enterprises achieve the triple goal of "reducing costs, increasing efficiency, and improving quality".

With its self-developed V-shaped rail core technology, Huiside Ring Guide Conveyor Line integrates the advantages of high durability, ultra-high precision, flexible customization, and low maintenance costs, and supports intelligent collaboration with various types of automation equipment. It is an ideal solution for automated conveying and assembly systems in the field of precision manufacturing.