Add time:2025-10-09

Add time:2025-10-09 clicks:

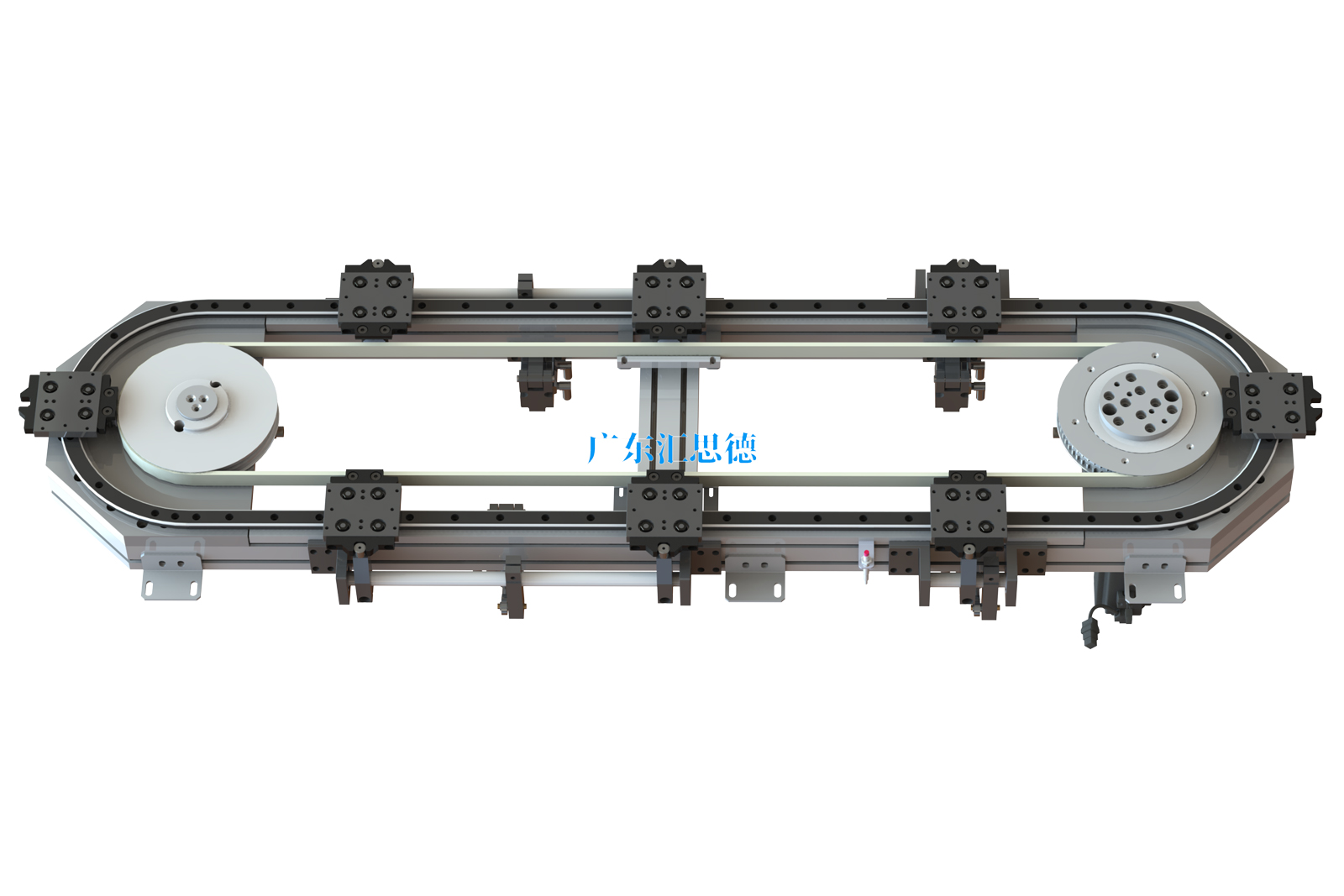

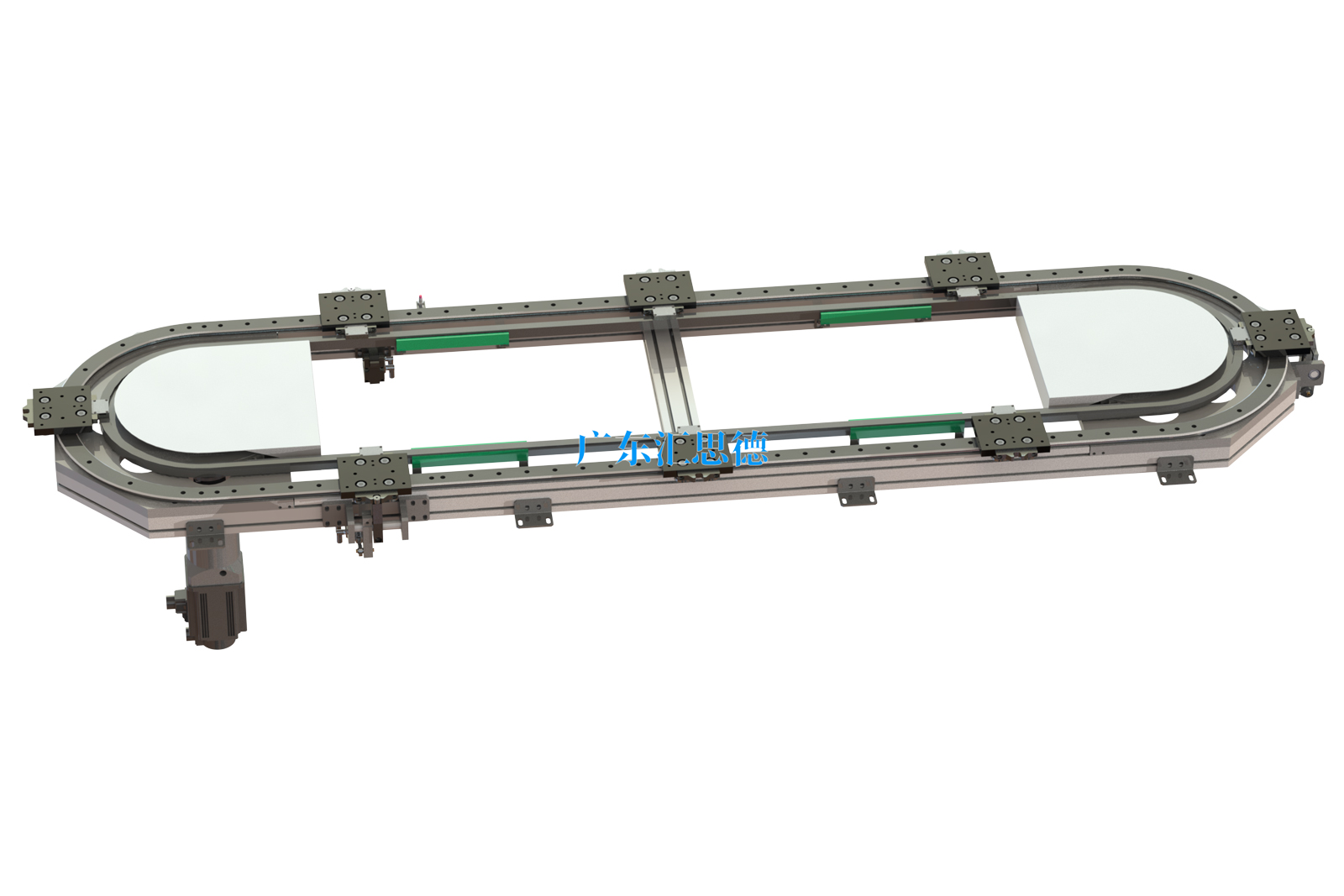

clicks: In the annular guide rail conveyor line system, synchronous belt drive and chain drive are the more commonly used transmission methods, which are widely used because of their high precision, easy production, convenient assembly, and easy maintenance. However, the choice of annular guide rail conveyor line in synchronous belt drive or chain drive is also different due to their own structure, physical characteristics, and performance.

Material: Polyurethane (PU) material is used as the main body, and spiral wound steel wire is used as the tensile layer, with moderate hardness.

Pitch: A timing belt with a pitch of 10mm or 20mm is usually used in the annular guide conveyor line, that is, the timing belt of AT10 or AT20.

Features: Good wear resistance, better load capacity than other materials synchronous belt. But slightly weaker in hydrolysis resistance or high temperature resistance.

Load: When using synchronous belt drive, the total load of the annular guide rail conveyor line is recommended to be within 300kg, and it is not recommended to be too large, especially in application scenarios with high speed requirements. The smaller the load, the better.

Pitch: The distance between the sliders on the annular guide conveyor line is limited by the spacing of the timing belt. For the timing belt of AT10, the spacing should be ≥ 100mm and the spacing should be an integer multiple of 10; for the timing belt of AT20, the spacing should be ≥ 100mm and the spacing should be an integer multiple of 20.

Length: The total length of the synchronous belt used in the annular guide conveyor line is recommended to be within 8 meters. It is not recommended to be too long. The longer the manufacturing cost, the higher the actual performance.

In the production and application of industrial automation, the circular guide rail conveyor line of synchronous belt drive is usually used in the application scenarios of high speed, light load, high cleanliness and short-distance circulation conveyor. Such as the pharmaceutical industry, semiconductor industry and digital electronics industry, the circular guide rail conveyor line of synchronous belt drive is more favored.

Materials: The most common materials for chains in circular guide rail conveyor lines are carbon steel, stainless steel, and alloy steel. Chains of different materials are used depending on the usage scenario.

Pitch: The chain pitch in the annular rail conveyor line is affected by the size of the chain. The most commonly used chain pitch is 12.7mm (8A), 19.05mm (12A), 25.4mm (16A), and 15.875mm (10A) and 31.75mm (20A) chains will also be used according to specific application requirements.

Features: High load strength, good wear resistance and temperature resistance, chains of different materials can be used according to different application scenarios. However, in order to prevent rust or smooth the chain usually needs lubrication, and grease contamination may exist in some application scenarios.

Load: The circular guide rail conveyor line of the chain drive can withstand higher tensile force and can be applied to application scenarios with high load and fast speed.

Spacing: The ring guide rail conveyor line of the chain drive, the center spacing between the slides is limited by the chain pitch. The center spacing between the slides needs to be > 100mm, and it is an integer multiple of the chain pitch. Of course, if it is an even multiple, it will be more convenient for production, manufacturing and post-maintenance.

Length: The length of the chain-driven annular guide rail conveyor line is more flexible, and it can be spliced to a suitable length according to demand, with a maximum length of about 200 meters.

In the application of industrial automation production lines, chain-driven annular guide rail conveyor lines are suitable for most industries, and are suitable for common high-speed, high-load, and long-distance circulation conveyor scenarios. Such as the automotive industry, new energy industry, home appliance industry, daily chemical industry, and other industries that require precision conveyor in automated production. Chain-driven annular guide rail conveyor lines are increasingly recognized and used by automation engineers due to their high load capacity, long service life, and high cost performance.

1. Accuracy

In the annular guide rail conveyor line, whether it is a synchronous belt drive or a chain drive, the accuracy achieved is relatively high. Without the secondary positioning mechanism, the pause accuracy can reach ± 0.5mm. After using the secondary positioning, the repeated positioning can achieve a pause accuracy of ± 0.05mm. In practical applications, for professional annular guide rail manufacturers, there is not much difference in the pause accuracy of synchronous belt drive and chain drive annular guide rail conveyor lines. Of course, the premise is that good precision chains and high-quality seamless steel curtain timing belts are used.

2. Noise

In the annular guide rail conveyor line, the difference between the synchronous belt drive and the chain drive is only in the transmission mode, and the structure of other parts is basically the same. The sound of friction between the belt and the synchronous wheel during the operation of the synchronous belt will indeed be smaller than the sound of the friction of the chain. However, in the application of the actual annular guide rail conveyor line, the annular guide rail conveyor line of the synchronous belt drive and the annular guide rail conveyor line of the chain drive will not be much lower in the overall noise during operation. Especially in the annular guide rail conveyor line with secondary positioning mechanism or high-speed conveying conditions, the noise of cylinder positioning, the sound of the motor running at high speed, and the sound of the sliding seat quickly bending are completely overshadowed by the sound of the synchronous belt or chain friction.

In the selection of the transmission mode of the annular guide rail conveyor line, one needs to consider the requirements of cleanliness in actual use, and the other is the need to consider the spacing. If there are no special requirements for the above two points, then we would recommend the use of chain transmission for the annular guide rail conveyor line. After all, it has better durability and higher cost performance.