Add time:2025-10-09

Add time:2025-10-09 clicks:

clicks: The process and material selection for manufacturing an annular guide rail requires considering several factors. Here are some important factors.

First of all, material selection is one of the important considerations when manufacturing circular guide rails. Guide rails need to have high strength, high hardness and wear resistance characteristics. Common guide materials include steel, cast iron, alloy steel, etc. Among them, steel is the most commonly used guide material because it has high strength and hardness, and is easy to process and maintain. For applications that require higher guide rail hardness, alloy steel can be selected.

Secondly, the manufacturing process is also one of the key factors affecting the manufacturing of annular guide rails. Common manufacturing processes include forging, casting, cold extrusion and grinding, etc. Forging is a commonly used process that can be used to make high-quality annular guide rails. Casting can make guide rails with complex shapes, but their materials may be relatively poor. Cold extrusion can complete the manufacturing of guide rails while maintaining high material strength. Grinding is a common method of manufacturing guide rails, which can achieve high-precision guide rail manufacturing, but at a higher cost.

There are some other factors to consider. The shape and size of the annular guide manufacturers will be designed according to the specific application requirements. Parameters such as the inner and outer diameter, height, width, straightness and surface quality of the guide rail need to be determined according to the specific use requirements. In addition, the lubrication and heat treatment of the guide rail are also very important. Lubrication can reduce friction and wear, while increasing the service life of the guide rail. Heat treatment can improve the hardness and strength of the guide rail, improve its impact resistance and corrosion resistance.

From the perspective of the environment and the use requirements, the guide rail needs to be able to adapt to different working environment conditions. For example, some guide rails will work in high temperature environments, so the characteristics of high temperature resistance need to be considered when selecting materials. In addition, the guide rail needs to have good corrosion resistance to resist the influence of corrosion factors such as humidity, acid and alkali. In some special application environments, the electrostatic conductivity and explosion-proof performance of the guide rail need to be considered.

In addition, cost is also one of the factors that need to be considered when manufacturing annular guide rails. Material cost and manufacturing process cost are the main factors affecting the manufacturing cost of guide rails. When choosing materials, material properties and cost factors need to be comprehensively considered to find the most suitable material. Similarly, in the manufacturing process, it is also necessary to weigh the costs and benefits of different processes to determine the most suitable manufacturing process.

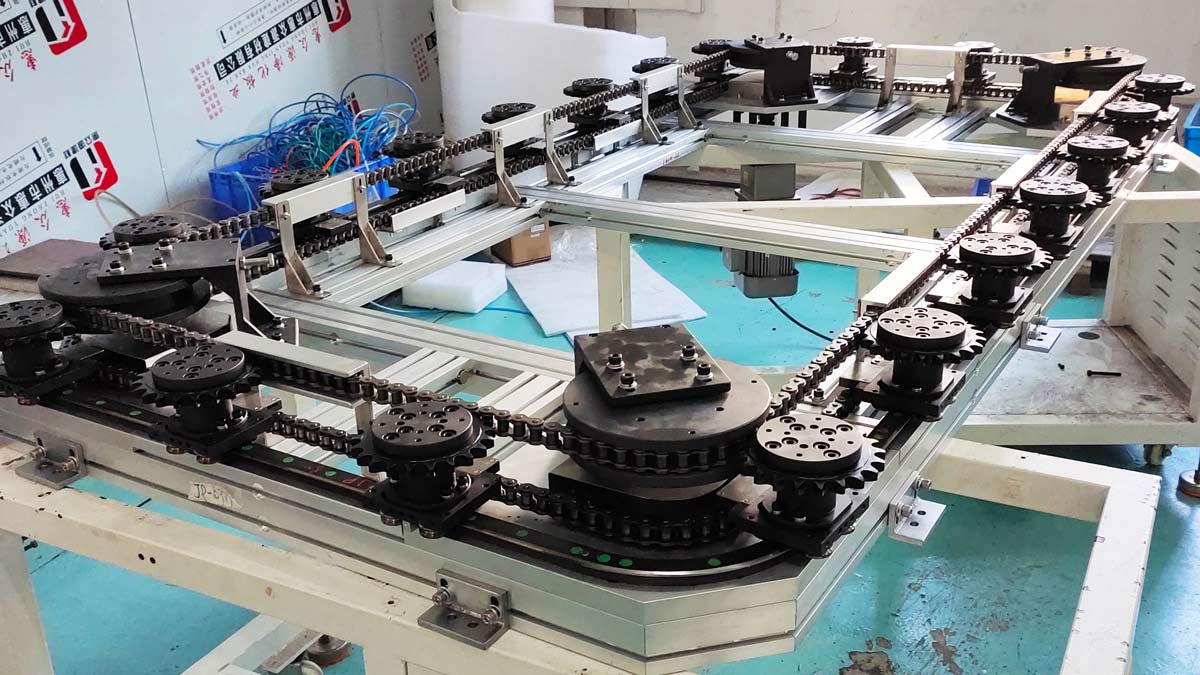

In general, the process and material selection when manufacturing the annular guide rail conveyor line need to consider a number of factors, including material properties, manufacturing process, environmental and use conditions, cost, etc. Under the premise of meeting the use requirements, these factors need to be considered comprehensively to find the most suitable process and material. This can ensure that the guide rail has good strength, hardness and wear resistance, adapts to various environmental conditions, and has a reasonable manufacturing cost.